Formative Engineering Pvt. Ltd. is a wrought iron hardware manufacturing company, situated in India, Ludhiana Punjab, having well-equipped and efficiently organized manufacturing facilities is essential to ensure smooth production processes and the delivery of high-quality products. Here's a blueprint for setting up such facilities:

Production Capacity

In full strength and using full production cycle we have capacity to produce 40,000 to 50,000 components every day.

Patent designs

We have some patent designs which we have not be purchased from other manufacturers.

Tool room

Separate in house tool room and state of the art technology to conceive and patent new designs. Tool Room Machinery includes VMC, CNC, Lasor Cut, Wire Cut, EDM etc.

Plants

Multiple plants with over 18,000 Square Yards of production area

Forging range

We can forge components ranging from 100Grams to 5 Kilo Grams.

Our Strength

Multiple plants with over 18,000 Square Yards of production area.

250+ Production + corporate and administration workforce.

6 hammers as primary forging machinery.

Monarch: Designing And Tooling

We have a separate tool room facility for tool and die manufacturing with well developed Design & Engineering facilities that can be comprises of :

- CAD/CAM for 3D modeling.

- Software of Art CAM for Die manufacturing on VMC Machines.

Monarch: Forging Facility

We have Screw Forging Press along with Metal Gathering units on these we produce the lifting components.

Our forging Unit is well equipped with following list of machines so that we can provide top quality components:

6 Hammers

2 Screw Forging

3 Metal Gathering

Monarch: Fabrication Facility

We have separate fabrication section equipped with following list of machines:-

4 Scrolling

6 Welding Sets

1 E.Hammering

1 Profile bending

7 Twisting for baskets and bars

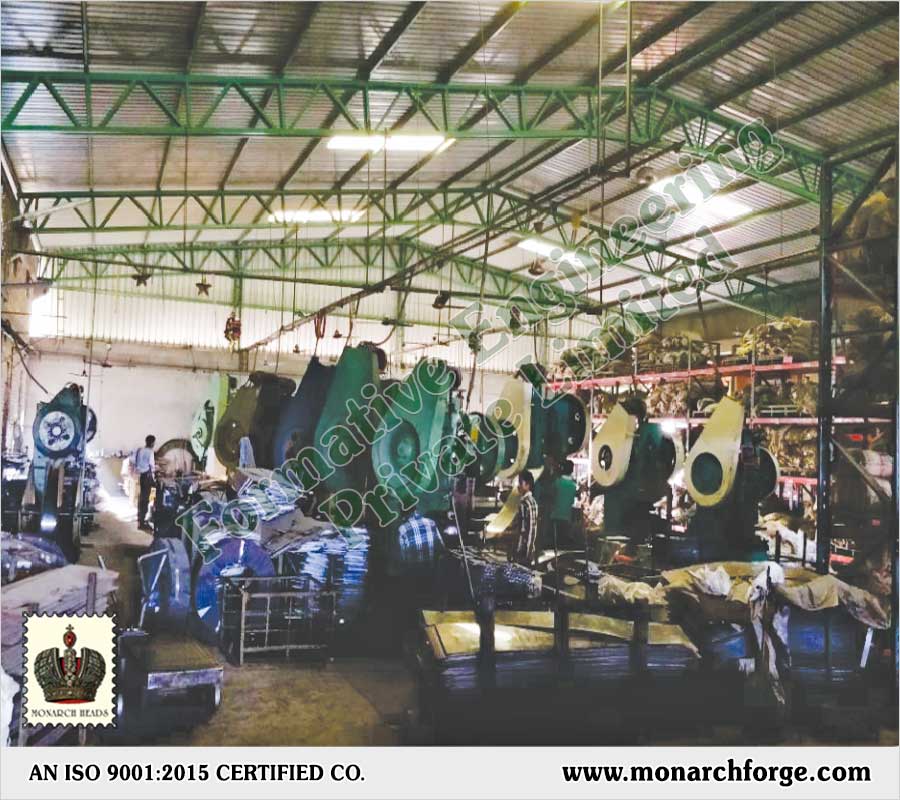

Monarch: Press Shop

Having press shop to manufacture pressed component with capacity of maximum 150 tons. press shop is equipped with the following machines:-

50 Presses having capacity of 20 tons to 200 tons

Monarch: Machining

We have ability to provide semi finished or fully machined parts.

Our machining facilities include:

12 Turning Machines

6 Drilling Machines

1 Riviting

Monarch: CNC Turning

CNC turning 5 nos.

Monarch: Testing & Validation

We do testing of every components starting from raw material procurement, in between all the manufacturing processes and before packing of material to ensure consistent level of quality components.

The inspection and testing facility include:

Chemical Test

Machanical test

Hardness testing

Calibration equipment

Lot or Batch Inspection

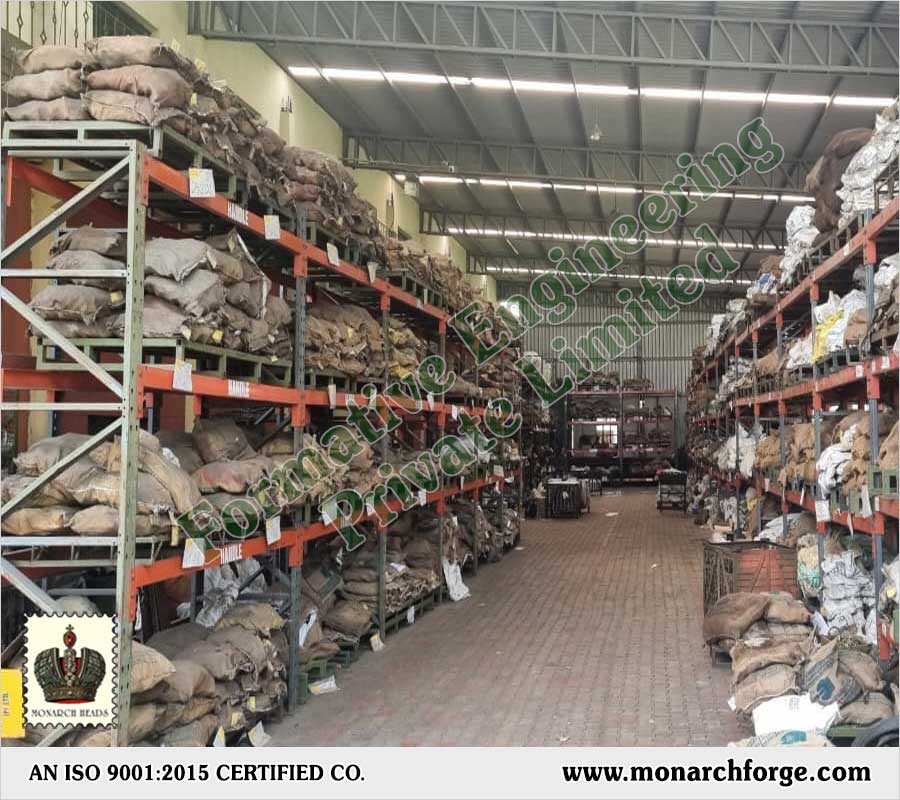

Monarch: Storage

Rack Storage system is followed in our factory to store the goods before it is being dispatch. We pack the material in steel crates and then they have been stored on the racks to safely store the material without any damage.